Alloy Towers

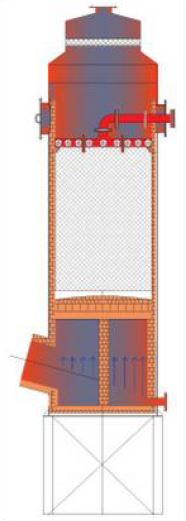

Acid towers in the Sulphuric Acid plants have historically been M.S. brick-lined. The acid proof brick-lining is to protect M.S. shell against corrosion caused by Sulphuric Acid. The advent of corrosion resistant alloy steels over the last few decades have brought a new and advanced solution for Acid Towers and its Internals. The Alloy Towers do not require brick-lining, as the base alloy itself has a very low corrosion in Sulphuric Acid. Alloy Acid Towers are lighter, fully weldable and can be partially or fully fabricated in workshop before bringing to site, significantly reducing installation time. Tower internals such as Packing Support, Distributor and other equipment can also be fabricated from corrosion resistant alloy steel.

Most modern Sulphuric Acid plants across the world now successfully use Alloy Acid Towers.

Comparison of Brick-Lined Acid Towers vs. Alloy Acid Towers

Conventional M.S. Brick-Lined Acid Towers

- M.S. requires chemical brick-lining significantly increasing complexity and installation time.

- Tower requires heavy structural support and foundation.

- Brick joints are susceptible to leaks, and leaks are extremely difficult to locate and repair.

- Brick arches are required for tower packing support, which significantly reduces area for gas flow. Gas flow pattern becomes non-uniform through power cross section.

- Cast Iron internals used in brick-lined towers such as Acid Distributors generates acid sludge which increase maintenance and reduce performance over time.

Alloy Acid Towers

- Can be prefabricated, requires no brick lining reducing complexity and installation time.

- Low weight, easy to install and requires a lighter structural support and foundation.

- Long service life, usually 20+ yrs. Minimal maintenance and downtime.

- No Bricks /Mortar debris entering and damaging the Acid Pump.

- Fully weldable, leaks can be quickly located and repaired resulting in a reliable operation.

- Better gas flow pattern with Alloy Grid Support and Alloy Distributors.

- Alloy internal give a clean and improved performance with low corrosion, and low iron content.

Features of Alloy Acid Towers - Alloy Internals

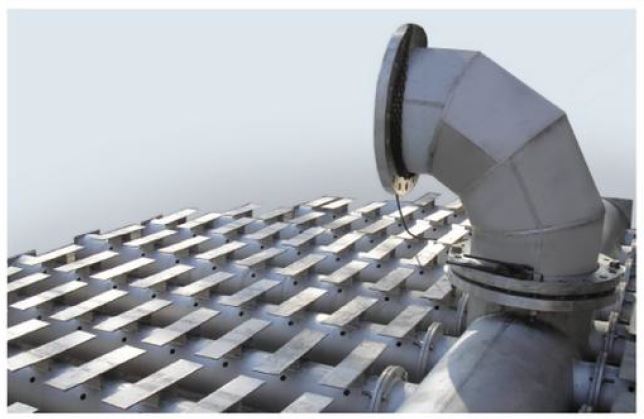

Alloy Packing Support

- Provides greater than 80% open area ensuring optimum gas flow distribution through the power packing.

- No need for layer of structured packing.

- Complete pre-fabrication in workshop reduces installation time compared to brick arches which needs to be made inside acid tower.

- Can be installed in Alloy or Brick-Lined Towers.

- Long life, as complete manufacturing is from Alloy material which has very low corrosion in Sulphuric Acid.

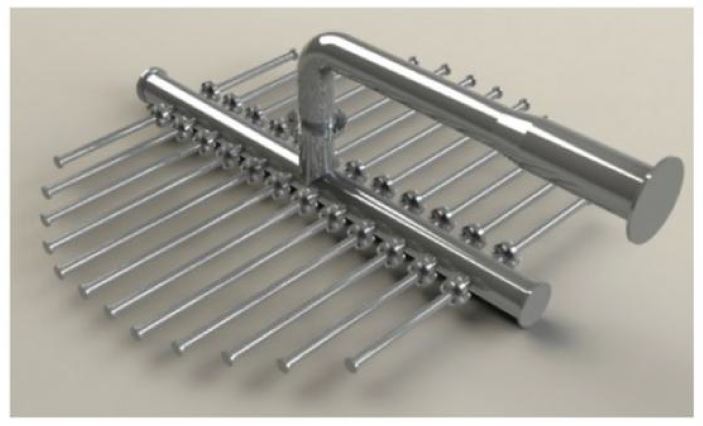

Alloy Distributors

- More Irrigation per unit area ~2-4x more orifices point.

- Uniform Distribution as distribution points will be evenly spaced.

- Operation in Sulphuric Acid will not change orifice diameter in Alloy Distributors due to low corrosion, therefore no change in performance.

- Low corrosion rate therefore no iron sulphate formation and acid sludge build-up in the tower.

- Easy to install and maintain.

- Low maintenance and therefore minimum downtime.